HERBORISTIC

COSMETIC

VEGETAL EXTRACTORS

Rapid

extractors for medical herbs

Essential

oil extractors

Mixers

- Emulsifiers

Hammer

mill

POLLUTING

CHEMICALS

Silver

recovery units

Concentrators

evaporators

WASTE

WATERS

Chemical-phisical

plant

Depurators

Resins plant

Reverse

osmosis

Ultrafiltration

APPLICATION

EXAMPLES

|

|

REVERSE

OSMOSIS

ULTRAFILTRATION

OVERVIEW

Today reverse osmosis represents the safest and most convenient

technique for the desalination of water of various sources. This

treatment replaces more and more other water desalination technologies

thanks to the optimum binomial between qualitative results and low

operating costs.

Advantages

In fact reverse osmosis guarantees reduced energy consumption and low

consumption of chemical products. Furthermore, the parameters of waste

water are within the limits for the discharge, thereby downsizing the

more than ever noted problem for the disposal of eluents (which exists

for example for water softeners and ion exchange resin demineralization

units).

HOW

IT WORKS

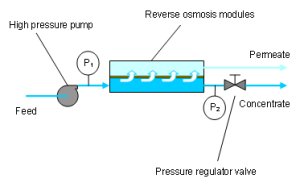

Reverse osmosis is the process that occurs when a saline solution is

placed into contact with a membrane that is absorbent to water (and not

dissolved salt) at a pressure that is over the osmotic pressure of the

solution itself. The passage of a water poor in salts (permeate) occurs

through the membrane, whereas on the outside of the membrane a waste

water rich in salts (concentrate) is obtained.

Recovery

factor = Permeate /

feed water x 100

Here

below is a list of the main

parameters that are used in the planning stage of reverse osmosis and

desalination processes:

- Salinity of the water to be treated

- Temperature of the water to be treated

- Recovery factor

- pH

- SDI

- Hardness

- Alkalinity

The comprehension of the water characteristics must be added to these

essential factors in particular, in order to improve possible

pre-treatment, it is fundamental to verify the presence

of:

- Suspended solids

- Polluting metals, such as iron and

manganese for

example

- Bacterial concentration

- Chlorine or oxidizing agents in general

(except

oxygen)

- organic substances, sulphides, oils.

PRE-TREATMENT

Before the reverse osmosis section it is important to determine the

most suitable “pre-treatment” based on the

characteristics

of the water to be treated so as to guarantee the greater operating

continuity of the system and reduce washing frequency. Correct

pre-treatment prevents relatively rapid lodgement of the membrane due

to grime and/or physical impurities, lodgement due to precipitation of

encrusting salts and/or metals, bacterial proliferation, contact with

oxidising agents.

USAGES

- Desalination of

brackish water to

obtain drinking,

irrigational or industrial water.

- Demineralising of well

or tap water for

industrial

use (heating plants, food, pharmaceutical, electronics industry, etc..).

- Desalination of sea

water to obtain

drinking water

OUR

STANDARD PRODUCTION

Our production of reverse osmosis units for the desalination of water

covers a wide range of solutions which are different based on:

- The type of water to

be treated, tap

water,

brackish or sea water;

- The type of use,

drinking water,

irrigational or

industrial water;

- The productive

capacity, from 200 l/h

to 25 m3/h of

permeate for brackish or tap water.

The desalination units efficiently operate in a continuous manner,

consequently the necessary productive capacity is given from the daily

need of permeate divided by the 24 hours that the unit is operating. It

is advisable to have an accumulation tank of the produced

permeate.

OPERATIONAL

LIMITS

In order to guarantee the long lasting performance of the membranes,

the intake water of the reverse osmosis unit must respect the following

limits:

- SDI < 3

- Iron <

0.05 mg/l

- Manganese <

0.05 mg/l

- Chlorine and

oxidant 0.0 mg/l

- Bacterial and organic

substances concentration

following the requirements of a drinking water

- Absence of oils,

sulphides and polluting substances

in general

Tap

or low salinity water

demineralising units

OVERVIEW

The

reverse osmosis tap water demineralising units are used for the

production of demineralised water for industrial use (heating plants,

food, pharmaceutics, electronics industry, etc..).

The models have productive capacities that range from 200 l/h to 2200

l/h of produced permeate. The demineralisation units efficiently

operate in a continuous manner, consequently the necessary productive

capacity is given from the daily need of permeate divided by the 24

hours that the unit is operating. It is advisable to have an

accumulation tank of the produced

permeate.

The desalinisation units are equipped with a sequestrant agent dosage

group that prevents the precipitation of incrusting salts on the

membranes. Furthermore, the unit may require an additional dosage group

or alternatively an active carbon filter to reduce the chlorine present

in the water to be treated. Post-treatment made up of a degassing tower

can be introduced in the event that it is necessary to eliminate the

carbon dioxide that is present in the permeate and increase the Ph. The

use of a station for the periodic washing of the membrane is always

advisable. For the production of ultrapure water the equipment consists

of mixed bed resins and UV after the dissalation unit.

|